Page 3 of 4

Posted: Fri Jun 10, 2005 7:16 pm

by weber

kneebar wrote:If you don't like lowering off a single point do what I do. Carry a couple of quick links and donate one on occasion, its not that big of a deal. The problem I have had in the past is some dumb-ass removes it. I don't get that, if you don't think you need it don't use it!

Although it is just one more thing to carry up with you, you might want to take along a small bottle of Loctite 242 (blue) to put on the threads of the quicklink. Then, no one can loosen the quicklink without a wrench. And, if you want to make the quicklink wrench-proof, use Loctite 262 (red.) With 262, a torch must be used to heat the quicklink above 300 degrees F to break down the compound to allow loosening with a wrench.

Rick

Posted: Fri Jun 10, 2005 8:43 pm

by kneebar

Rick, good idea!

I have a bottle of the red stuff around here somewhere.........I'll just have to make sure I don't get it on the cams!

Posted: Sat Jun 11, 2005 1:57 am

by Wes

Please don't put locktight on screw links, because other people might think they are in a bad spot and want to remove them.

Posted: Mon Jun 20, 2005 6:46 pm

by Caspian

Question:

Of the developed clifflines in the online guide, can anyone provide clarification for which crags are on Forest Service Property and any other exceptions where there is no route developement allowed?

Posted: Mon Jun 20, 2005 9:58 pm

by ynot

Buy a map. Its not hard to figure out.

Posted: Tue Jun 21, 2005 5:11 am

by goodguy

Let me just say that I have seen some pretty scary stuff at the Gorge over the years. Almost all of these have to do with climbers and belayers, not how many points I have to lower from.

I personally have taken a stainless steel Rap Ring from FIXE, which is the piece of gear that is in question, and tried cutting it with the biggest bolt cutters I could find. I even tried using a Blow Torch to melt it in half. Neither of which would do anything. I had to use an angle grinder with a very thin brand new disc to cut it.

After going through all this to satisfy my issues with how strong these things were, I've decided that I'll take a single Rap-Ring, Belay loop, Biner, Rope etc.....

Over a belayer or climber who I have no way of knowing truely anything about by simply testing pull strengths and finding out the facts.

I mean when you go to the Gorge and people are drinking, smoking dope, using who knows what types of other drugs while climbing or belaying, I think the gear is the least of a lot of peoples worries.

Posted: Wed Jun 22, 2005 1:10 pm

by weber

Wes wrote:Please don't put locktight on screw links, because other people might think they are in a bad spot and want to remove them.

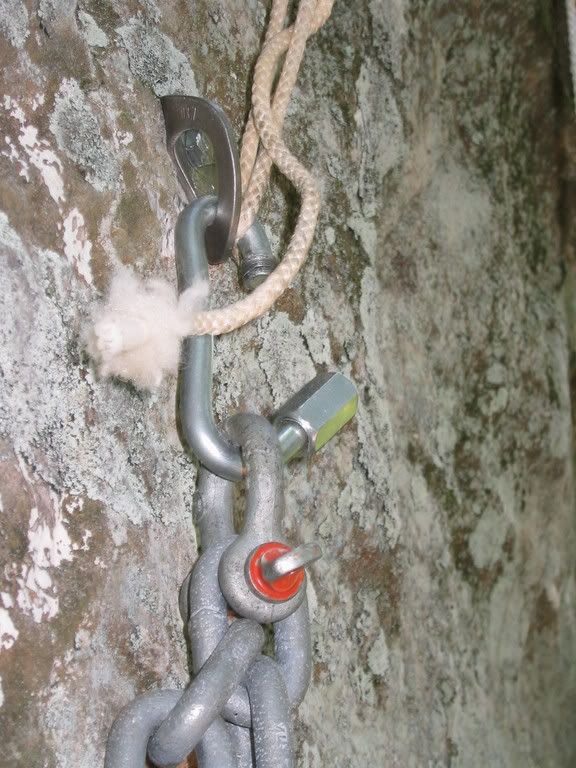

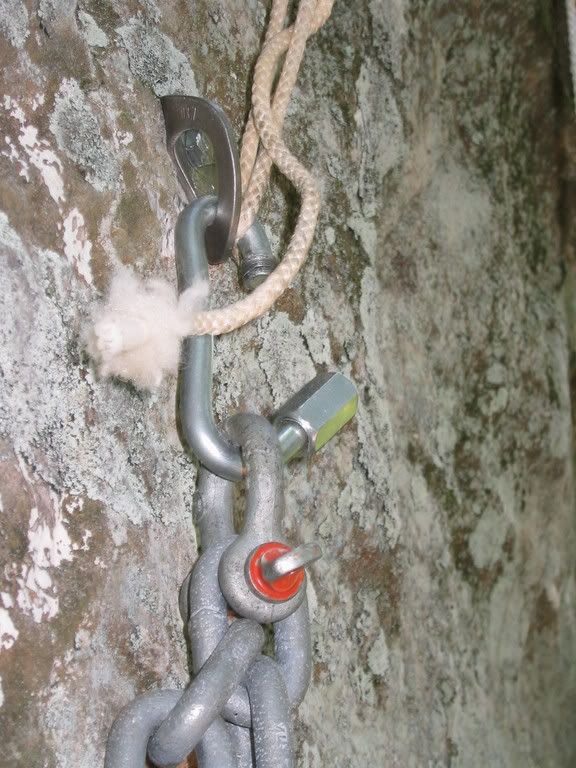

Guess I'm not sure I understand, Wes. To clarify my comment: I suggest that qualified route developers put Loctite on screw links installed on top anchors -- either in conjunction with or without chains, depending on the configuration the developer chose for that particular anchor system. Those of you who saw the quick link blow out at the testing portion of the Bolting Clinic at Muir during Rawk n Rawkus saw how dangerously weak a partially threaded quick link can be. Locktite, properly applied, can ensure the things stay fully threaded.

If a climber uses quicklinks in addition to the ones originally installed at the top anchors, or he chooses to bail on one elsewhere on a hanger on the route, then that is a different matter. In this case many climbers would consider the screw link (without Loctite) to be booty.

Regardless, there are many opinions on what hardware to use and how to place it. It is often amusing to see two well-respected route developers ferverently disagree on how a route should be bolted and what hardware to use. Most often, the truth is that they are both right. Just two different opinions.

The bottom line is that if you choose to use a quick link, and if you choose to Loctite it, be sure the thing is fully threaded closed. Red Loctite is permanent (short of torching it.) And, blue Loctite allows unthreading with a wrench.

Rick

Posted: Wed Jun 22, 2005 1:49 pm

by Wes

If you ever want to replace/change the screwlinks and they have locktight on them, you would have to cut them off, which sounds fine in theory, but is much harder to deal with on the route. Because sooner or later, they will need to be replaced. Like the big 1/2 inch one on awol - I couldn't get it off, and now it is in the way of the new setup. The only think to do is to totally replace the anchor now, or haul a torch or something up there.

Posted: Wed Jun 22, 2005 3:44 pm

by weber

Wes wrote:If you ever want to replace/change the screwlinks and they have locktight on them, you would have to cut them off, which sounds fine in theory, but is much harder to deal with on the route. Because sooner or later, they will need to be replaced. Like the big 1/2 inch one on awol - I couldn't get it off, and now it is in the way of the new setup. The only think to do is to totally replace the anchor now, or haul a torch or something up there.

If red Loctite has been applied, the threads can be heated above 400 degrees F to break down the chemical bond. Then, they unthread fairly easily. I use a small butane torch with built-in piezo electric lighter. Weighs a few ounces -- small than a Red Bull can. You can get one at:

http://www.micromark.com

A 3/8-inch quick link can be heated to 400 d in about 30 seconds. Sure beats sawing. Plus, the quick link, if it is in good shape, can be reused.

Rick

Posted: Wed Jun 22, 2005 4:04 pm

by squeezindlemmon

That's a great idea, Rick. Esp after seeing how that quicklink just popped right at the threads during testing!